Applying Vastu for Industrial Buildings and Factory Design

In fact, Vastu concepts emphasizing productivity, unobstructed workflow, safety considerations and mitigation of hazardous elements hold even more relevance in industrial spaces where human efficiency, machinery operations and environmental factors play a crucial role.

Here’s an in-depth look at implementing authentic Vastu principles for optimal design of industrial buildings and factory facilities:

Site Selection and Land Configuration

One of the foremost aspects in traditional Vastu involves carefully evaluating and preparing the land parcel itself based on geomantic guidelines. Factors like soil composition, terrain contours, presence of water bodies, vegetation and energetic grid alignments are studied before planning construction.

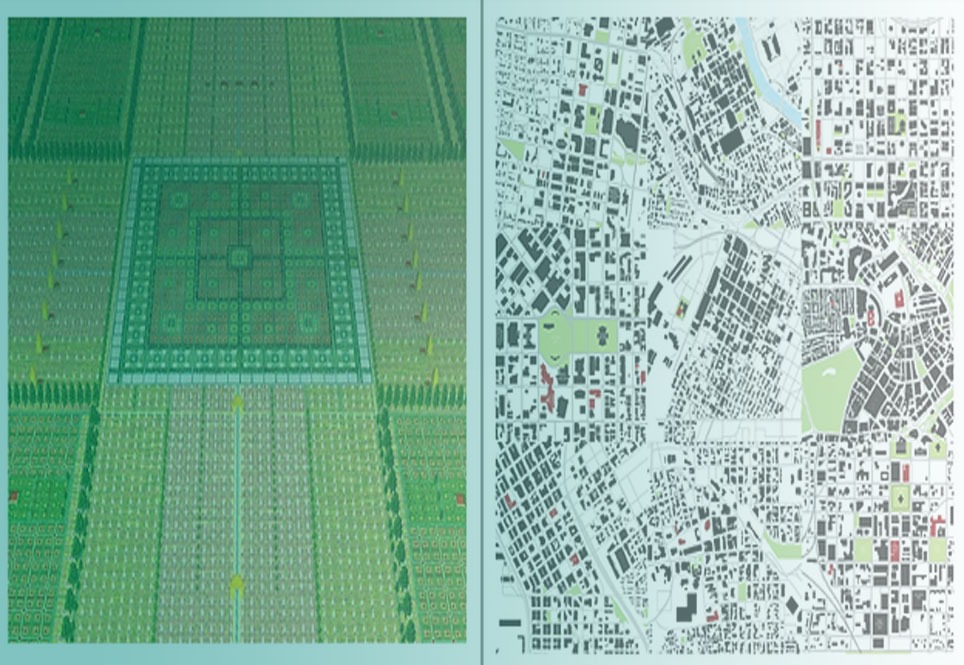

For industrial developments, soil testing is conducted to analyze the bearing capacity, identify potential geopathic stress zones from underground streams/faultlines, and ensure a robust, hazard-free foundation. The land’s geometric layout is then configured into a square/rectangular grid with the main factory complex oriented along the central spine.

Building Alignments and Zoning

As per Vastu guidelines, industrial structures should ideally have a square-shaped geometry with openings and exits planned facing the auspicious east or north-east directions to attract growth energies. However, practical factors like production logistics and material flows may necessitate other orientation alignments.

In such cases, remedial measures like placing sculptures of animals like elephants, horses or bulls at strategic spots can mitigate design misalignments and ensure auspicious energy flows throughout the facility.

The core factory area is recommended in the central Brahmasthana square, flanked by warehouse/storage zones in the southwest and northwest. Employee amenities like canteens, locker rooms and fire stations should occupy the southeast quadrant. Administrative offices are best positioned in the northeast zone. Utilities like boiler rooms and effluent treatment plants are placed in the inauspicious south/southwest zones.

Material Flows and Workflows

Vastu advocates unobstructed, streamlined flows for both raw materials and production processes to enhance efficiency and prosperity. So entrances and internal pathways have to be carefully planned to avoid any energy stagnations or obstructive corners where materials/personnel could get stuck.

The layout is optimized with gentle curves, ample circulation space and graded slopes instead of harsh turns or choppy movements that create energetic roadblocks. Machines should be oriented so that the operators face favourable directions while working.

Apart from linear assembly lines, Vastu also offers zonal cluster arrangements where complementary processes/functions are grouped together in specific energy zones to create synergistic workflows and idea cross-pollination.

Machinery and Utility Placements

Traditional Vastu offers precise guidelines on placing various industrial assets like heavy machinery, storage tanks, transformers and utilities to ensure equipment longevity while safeguarding human occupants from potential hazards.

For instance, high-temperature process utilities like furnaces and boilers should ideally be positioned in the southeast quadrant to mitigate fire risks. Wastewater treatment systems are recommended in the south zone to channel outflows properly.

Overhead tanks and piping systems are avoided above critical work zones to eliminate potential dangers from leaks or structural failures. Rotating machines and flywheels are aligned along specific energy vortices to optimize their efficiency and driveshaft alignments.

Resource Conservation and Sustainability

Several aspects of traditional Vastu architecture have strong parallels to modern principles of green building design and industrial sustainability. The emphasis on maximizing natural lighting and ventilation, rainwater conservation through aquifer recharge, avoiding wasteful resource utilization, minimizing carbon footprints through localized material sourcing etc. are all inherent to Vastu’s earth-centric philosophies.

Factory campuses designed per Vastu guidelines incorporate passive cooling through wind tunnels and strategically placed courtyards with cooling plants/shrubs. Sustainable drainage and sewage systems are incorporated using slopes and gravity feeds instead of energy-guzzling pumps.

Implementation Challenges

Despite its compelling benefits, applying authentic Vastu guidelines to industrial buildings does face some unique challenges compared to residential projects. Functional and logistical requirements often supersede energetic alignments and human-centric philosophies in factory design due to the scale and nature of operations.

Machinery dimensions, production workflows and material handling needs tend to take precedence over precise geometric grids and zonal placements recommended by Vastu. Getting permits and approvals for traditional materials like adobe or rammed earth construction can be difficult due to industrial building codes.

However, leading corporations are increasingly exploring ways to harmonize the rational concepts of Vastu with modern industrial design sensibilities and sustainability goals.

Real-World Examples

Several reputed industrial players have successfully implemented core Vastu principles in various high-performance green facilities globally to enhance employee wellbeing, productivity and resource optimization:

Infosys, India’s IT bellwether, applied Vastu concepts like road zig-zags, avoidance of overhead tanks and sloping roofs in designing its new software development campus in Hubballi, allowing them to save over 30% in energy costs.

German automaker BMW incorporated traditional Vastu architectural elements like abundant natural lighting, natural ventilation, water recycling systems and strategic placements of courtyards, gardens and walkways in its manufacturing facility near Chennai, India.

Darsalam, one of India’s largest grain processors has adopted various Vastu recommendations like optimal machinery layouts, staggered roof formations and vastu-compliant raw material/product flow patterns in their state-of-the-art production units across the country.

Panacea Biotec, a leading Indian pharmaceutical company worked closely with Vastu consultants to meticulously analyze planetary alignments and incorporate Vastu tenets in the design of their multiple manufacturing facilities for improved productivity, efficiency and workplace quality.

The principles of Vastu Shastra aim to synergize the cosmic forces of nature with the built environment to create productive, nurturing spaces that foster growth and prosperity. While factory design has to balance both functional logistics and metaphysical ideologies, the core human-centric philosophies behind Vastu offer an insightful framework for optimizing spatial energy flows and enhancing overall manufacturing efficiencies.

In a competitive landscape where operational excellence, resource optimization and workforce wellbeing are key drivers of industrial success, applying the rational thought processes behind Vastu’s ancient architectural wisdom can be a potential game-changer when done thoughtfully.